Design of prefabricated steel frame houses: Learn Drawings, Structures & Construction Processes from A-Z

What is prefabricated steel house?

First, before you learn about the design as well as the benefits or advantages of using prefabricated steel buildings, you should know what is pre-engineered steel buildings?

As we all know, most construction and construction works have been using cement and reinforcement for the past, making each of our houses sustainable and providing certainty for every house before every storm, rain and wind … However, with the development of science and technology to develop new types of factories. By using the steel frame, it created the construction items with many impressive designs, ensuring the safety and solidity for all houses and bringing many special features.

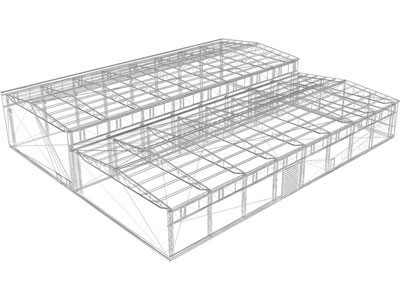

Pre-engineered steel buildings are known as construction works designed according to architectural drawings, then processed parts to be installed at the factory, then brought to install immediately at the construction site. Pre-engineered steel buildings are models applied to warehouses, factories, supermarkets, garages, civil houses, …

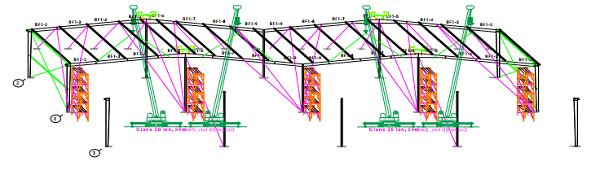

With main materials used are steel frames, beams, purlin and roof. Beam and column components are manufactured according to the design with the correct parameters at the factory and then assembled together by bolts link to create a most complete construction.

Drawings of pre-engineered steel buildings & notes

The construction of factories or industrial warehouses, car parks, … with steel frame design is one of the models selected by many businesses and companies by many advantages and advantages. benefits that this type of construction brings.

According to the design and construction experts, you should first be aware when making drawings of pre-engineered steel buildings for your project:

- – First of all, it is necessary to arrange the ground to be suitable with the current diagram as well as plans to expand the steel truss system in the future.

- – Make plans for specific design of the main structure.

- – Documents using pre-engineered steel buildings design, construction drawings must ensure adequate technical factors and parameters.

- – The types of materials used and structural details must conform to the applicable standards to provide safety for steel frame houses.

- – Need to calculate carefully to be able to save the maximum cost for investors and still ensure the quality for the project.

How is residential prefabricated housing?

When referring to the model of prefabricated housing, many people always think about rigid, rough factory models. However, models of civil prefabricated houses with simple scale, impressive design and modern architecture will make you feel surprised about a model of housing with space more attractive than architecture. Design of conventional reinforced concrete houses.

Civil prefabricated house is a modern construction work with the use of industrial steel as a main pillar, which brings many advantages that conventional housing model cannot have.

With the model of building prefabricated houses, it will bring a lot of superiority such as:

– Easy to design and build according to your wishes: Currently, to get a home that fits your liking and has a unique design that is simple, architects can easily Bring you the most suitable designs with simple prefabricated models that fit your desires.

– Minimize construction costs: With the construction of pre-engineered steel buildings, you do not need to worry about the cost of construction. With prefabricated houses will help minimize your construction costs compared to conventional reinforced concrete houses.

– Rapid construction time: With the installation and production of steel pillars at the workshop, it will help the construction and installation of construction works become faster and save a lot of time.

– Easy to maintain and move: Besides, construction works with prefabricated houses are easy to maintain and move when there are changes in environment and living places.

2-storey steel frame house

A complete 2-storey pre-engineered steel frame house is carried out through 3 main phases: designing, processing and assembling houses at construction sites. First, the architect will design and calculate the amount of steel used to suit your home.

The steel pillars are calculated in accordance with the durability of the house. Then, the mass of steel cylinders will be machined in the workshop and taken to your construction site for assembly.

There are many people worried about using prefabricated steel that will make your house not durable enough to withstand the force of building high-rise buildings. However, with the following advantages that the 2-storey prefabricated house will surely make your worries be answered.

– Good bearing: With the amount of steel pillars built by architects, the parts of the house must bear little pressure to minimize the amount of steel to make the steel frame of the house become should be lighter and help you save the most construction materials.

–Can build a large housing model: With the construction of a pre-engineered steel frame, it will help you to build houses with large and large scale. You can build tall buildings without worrying about the durability or strength of the house. Therefore, there are many models of high-rise houses built with prefabricated steel frames.

– Save construction time: The construction of a 2-storey house with pre-engineered steel frame also helps homeowners can save construction time compared to the construction of conventional reinforced concrete houses. Because of the fabrication of structural details available at the factory and brought to the construction site for complete assembly, it is easy to speed up the construction progress, thus saving a lot of time. construction.

– Construction cost savings: Helping homeowners save a lot of construction costs. Although the cost of pre-engineered steel frames is expensive, but it saves costs due to shortening construction time, the cost of construction workers and construction supervisors from there to help homeowners can save a lot.

Unit price for construction of prefabricated steel frame factory.

There are 5 broad factors affecting the construction price of prefabricated steel frame factory.

– Design cost: This is the cost you need to spend when you want to build a safe, secure and economical factory. The design hire will help you to calculate the volume of materials to be sold to be suitable and economical. Design will help your factory get the best design and science.

– Construction area: The construction area is also a major influence on construction costs as the larger steel buildings will make you more raw materials than smaller houses.

– Construction materials: With a prefabricated factory, construction materials will not cost much compared to civil prefabricated houses because there is no need for too many construction materials to increase the aesthetics for houses. such as glass, wood, etc. However, to create a solid and durable factory, you should also invest more in building materials mainly for your construction such as steel or other materials. In addition, construction materials are also subject to price adjustment depending on the supplier or each year according to the price of goods on the market. Therefore, you should choose the unit price according to the current price to avoid confusion and have a specific price list, best.

– Labor cost: In order for your construction to be constructed with good quality and fast time, it is indispensable to abandon the cost of hiring labor when you want to build this factory. You should have yourself a suitable choice to get the best skilled worker.

– Steel trusses price: This is the key point that greatly affects your construction work. Every year there is a change in the price of steel buildings that make the owners feel anxious about the unit price of construction. However, there are also years when this material reduces cost, so you can save construction costs. If you are looking to build a prefabricated house at a low cost, you should consult the price of the current steel frame.

If there is a need to build a prefabricated factory, you should consult the unit prices for the construction of a pre-engineered steel frame factory so that your costs can be easily estimated. The current construction price of prefabricated houses is usually calculated in m2 because the volume of steel is very important when calculating the price of steel buildings. Due to the complexity of the design of buildings, it will be very easy to affect the price of your construction works, so it is difficult to get the correctness by the amount of steel.

In addition, the construction unit price also has the weight and size of the structural parts on the factory, the complexity of the links, the construction site, the shape of the beam and the floor structure.

The unit price applied for the pre-cast concrete pre-engineered steel frame factory is currently in the range of 450,000VND / M2 – 1,200,000VND / M2. In addition, depending on other costs, the price may vary.

Construction of high-rise steel structure buildings.

Construction of high-rise steel structure buildings is different from traditional concrete

– In fact, it has been proved that buildings over 15 floors built from steel structure will save more than traditional concrete construction. This is more practical and clear when seeing the bearing capacity of steel on seismic areas.

– Today, with advanced technology and latest innovations, scientists have successfully researched the combination of concrete and steel in construction, especially high-rise buildings. Applying such design not only saves costs but also ensures fast construction progress.

– It is obvious that building a high-rise building with steel structure can only take half the time compared to concrete construction. For example, to build a 25-storey building takes about 24 months to build in concrete but with steel structure, it only takes about 12 months to complete. Shortening such a long time will bring many benefits to investors and the return of capital is quick and sooner. This is an effective solution for big cities that are considered the symbol of a prosperous city with high-rise buildings growing with the rapid development of the city.

Do townhouses with steel frame structure bring sustainability?

Model of building a town house with steel frame structure is being a popular construction model. However, not everyone knows this construction model well. Do many skeptics make a town with this steel frame structure to bring sustainability to your home?

Building townhouses with steel frame structures is the construction of steel pillars with solid construction installed with architectural drawings with the ratio calculated accurately instead of using conventional reinforced concrete. Because of the ability to withstand drag, compression, bending of steel much higher than reinforced concrete, it is easy to design loads with smaller cross-sections than reinforced concrete.

Quality can be easily controlled due to the centralized production at the factory. Not only that the structure of construction works with steel frame houses is also constructed with the foundation structure is still reinforced concrete foundation to transmit the upper load to the soil below. Along with that are the nail bolts pre-placed on the nail system before pouring concrete to ensure the column components, beams make it easy and accurate.

Models of beautiful prefabricated steel frame houses

Models of pre-engineered pre-engineered steel frame houses depend not only on beautiful aesthetic and architectural elements but also on the appropriateness of the calculation of length, width, and height parameters. It also has to withstand the effects of weather, sound insulation, and insulation effectively for the project.

In order to get yourself beautiful pre-engineered steel frame houses, investors as well as designers, architects and construction department need to coordinate with each other based on design drawings to be able to install The best home framing.

In fact, there are many conflicting opinions between designers and investors. Designers offer standard design drawings, reasonable calculations and cost savings, but do not make investors feel satisfied. And vice versa, investors’ expectations are not consistent with the current construction situation, causing many difficulties for the construction, leading to difficulties with beautiful prefabricated steel frame houses. .

Currently, architects also offer a variety of designs as well as design drawings for pre-engineered steel frame houses that meet quality factors, save costs, optimize public space. construction process, using environmentally friendly and economical materials. The model of pre-engineered pre-engineered steel frame houses with smart optimal saving designs is also the product that many customers prefer today.

Should or not to build houses with a cheap prefabricated steel frame

At present, the construction of a cheap prefabricated steel frame house is a tendency of many people to build houses. Different from the conventional way of thinking that simple prefabricated houses always bring comfort and modernity in the skillful design of architects.

In order to meet the desires of people about a comfortable, convenient, luxurious and economical home, architects have designed prefabricated houses with modern architecture, with a cool space to display. Scientific position comes with luxurious furniture to help the space of the house in accordance with the contemporary style and in accordance with the requirements of the house owner.

Especially with the use of lightweight construction materials with good physical properties to help with sound insulation and heat reduction to help your prefabricated house overcome all disadvantages of noise as well as temperature. Bringing you a more modern and comfortable living space than the construction of conventional reinforced concrete houses.

The company designs prestigious prestige steel frame houses.

Providing customers with products of the best quality must require drawings and designs to be accurate and consistent with the requirements that customers set. Come to Le Hong Construction and Steel Structure Joint Stock Company to provide the best pre-engineered steel frame design service.

When customers use the service, Le Hong Steel will provide specific advice on appropriate solutions right after starting the construction project to ensure the quality of the project to the final stage.

The company will calculate and give drawings, designs with high accuracy, minimize the wear and waste in the construction process and ensure the safety, sustainability and aesthetics for the company. submit.

With many years of experience in industrial construction and pre-engineered steel frame houses. PH VICKHOME always satisfies the requirements given by customers as well as gives customers the services with cost savings and high economic efficiency.

With a team of engineers, skilled workers combined with modern machinery and equipment to help the construction process always ensure in terms of technical supervision, speeding up the progress and quality of the project.

For more information, please contact us immediately: